Рейтинг: 4.5/5.0 (1869 проголосовавших)

Рейтинг: 4.5/5.0 (1869 проголосовавших)Категория: Windows: Плееры

20 Октябрь 2014

Была на собеседовании, впечатления отвратительные. Зря потратила время. Это не курсы, это какой-то театр одного актёра, то есть, Виктории, которая никак не может сложить цену себе и своим «уникальнейшим методикам».

30 Июль 2013

Была у них на собеседовании. Перед собеседованием мне позвонили в ответ на моё резюме ( которое я отправляла на двух языках: русском и английском) и спросили, владею ли я английским языком. Мне следовало уже после этого глупого вопроса сделать выводы о том, какой из Виктории работодатель. Но мой прирождённый оптимизм взял верх, и я таки пошла к ним на интервью. В приёмной меня встретила хамоватая девушка Ксения и со скучающим видом сказала подождать. Потом вышла Сама, провела меня в комнатку, показала свои цветные распечаточки, называя их попутно «авторской методикой». Хотя авторского там только и всего, что разноцветные буковки. Держала себя высокомерно, нахваливала свою псевдометодику, мои вопросы почти всегда игнорировала. Вышла оттуда с ощущением, что побывала в каком-то параллельном мире.

Меж тем, вакансия всё обновляется и обновляется. И больше всего мне нравится фишка с сопроводительным письмом, в котором человек должен расписать, почему он считает себя достойным кандидатом на эту позицию. Много пафоса, много мишуры и разноцветных буковок, но вместе с тем, у сотрудников и у директора напрочь отсутствует понятие о том, как общаться с соискателями. Такое ощущение, что каждый, кого пригласили на интервью, изначально шёл к ним просить милостыню.

В общем, ищут такого, чтоб, с одной стороны, был каким-никаким, а специалистом, а с другой стороны, чтобы был истинным буддистом, которому на всё по барабану

Не советую этого работодателя.

VLS may refer to:

* Vapor-Liquid-Solid method. a method to grow nanocrystal

* Vertical Launching System

* Von Luschan's chromatic scale a scale for detirmining skin colour.

Look at other dictionaries:VLS — puede referirse a: VideoLAN servidor Las siglas en portugues de Veiculo Lancador de Satelites, una familia de cohetes desarrollados en Brasil. Las siglas en ingles de Vertical Launching System, un sistema de lanzamiento vertical de misiles… … Wikipedia Espanol

Vls — Vls, Abbreviatur fur Vlamisch … Pierer's Universal-Lexikon

VLS — Die Abkurzung VLS steht fur: Vandenberg Launch Site bzw. Vandenberg Landing Site Vapour Liquid Solid, eine Wachstumsmethode von Halbleitern Vascular Leak Syndrom, eine potenzielle Nebenwirkung bei der Therapie mit Interleukin 2… … Deutsch Wikipedia

VLS — Cette page d’homonymie repertorie les differents sujets et articles partageant un meme nom. VideoLAN Server, un logiciel libre de diffusion multimedia sur reseau. L acronyme de Velos en libre service, un systeme de mise a disposition de… … Wikipedia en Francais

VLS — VideoLAN Server (Computing » Networking) Vertical Launch System (Governmental » Military) Veiculo Lancador De Satelites (Governmental » NASA) * Virtual Learning System (Community » Educational) * Village Voice Literary Supplement (Community »… … Abbreviations dictionary

VLS — vascular leak syndrome; visible light spectroscopy … Medical dictionary

VLS — • Volume Loadability Speed ( > IEEE Standard Dictionary ) • Vandenberg Launch/Landing Site ( > IEEE Standard Dictionary ) Luftfahrt / Raumfahrt … Acronyms

vls — ISO 639 3 Code of Language ISO 639 2/B Code. ISO 639 2/T Code. ISO 639 1 Code. Scope. Individual Language Type. Living Language Name. Vlaams … Names of Languages ISO 639-3

VLS — [1] Volume Loadability Speed ( > IEEE Standard Dictionary ) [2] Vandenberg Launch/Landing Site ( > IEEE Standard Dictionary )

VLS — Vandenberg Launch and Landing Site Contributor: CASI … NASA Acronyms

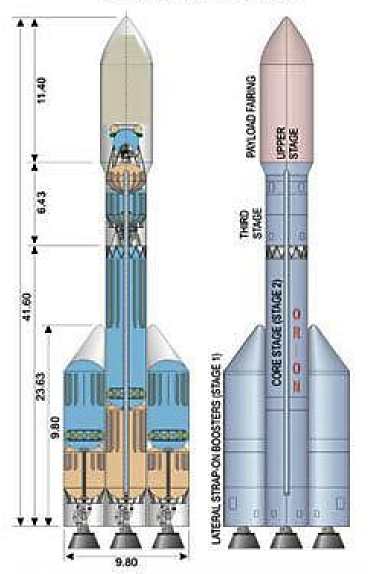

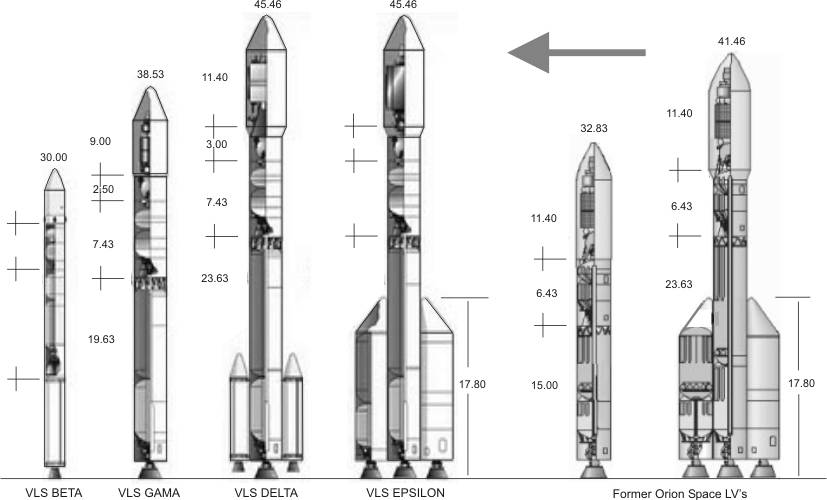

VLS Launch Vehicle

Brazilian VLS space launcher in its launch complex at Alcantara.

Brazilian satellite launcher building on successful family of sounding rockets.

LEO Payload: 380 kg (830 lb) to a 200 km orbit at 5.00 degrees. Payload: 80 kg (176 lb) to a 800 km SSO. Failures: 4. Success Rate: 42.86%. First Fail Date: 1985-12-01. Last Fail Date: 2003-08-22. Launch data is: continuing. Development Cost $: 300.000 million in 1999 dollars. Flyaway Unit Cost $: 8.000 million in 1990 dollars.

Stage Data - VLSAKA. Veiculo Lancador de Satelites.

Payload. 380 kg (830 lb).

Height. 19.50 m (63.90 ft).

Diameter. 1.00 m (3.20 ft).

Thrust. 1,048.90 kN (235,802 lbf).

Apogee. 200 km (120 mi).

First Launch. 1985.12.01.

Современные условия рыночной конкуренции требуют от каждой компании прилагать максимум усилий для снижения себестоимости предоставляемых услуг и товаров. Но всем понятно, что резервы экономии прямых затрат не безграничны. Поэтому, многие зарубежные компании уже давно снижают непрямые затраты, влияющие на себестоимость. К таким непрямым затратам относятся издержки на содержание дополнительного персонала, не принимающего непосредственно участия в создании прибыльного продукта или необходимость в котором носит временный характер. Ими используется аутсорсинг (от outer-source-using, outsourcing – применение внешнего ресурса) или аутстаффинг (от outstaffing, out — "вне" + staff — "штат" - применение внештатных сотрудников). Также распространено применение лизинга рабочих.

Группа компаний "ВЛС" готова взять на себя решение этих задач! Мы находимся в Москве, но предоставляем свои услуги компаниям по всей России, имеем внушительный опыт работы в этой сфере и высококвалифицированные кадры. Сделать заказ очень просто и займет совсем немного времени.

С нами уже сотрудничают десятки московских компаний и большое количество организаций из разных городов нашей страны. Клиентами аутсорсинговой фирмы "ВЛС" становятся как малые предприятия, так и крупные интернациональные организации. С 2006 года мы оказываем услуги по подбору и организации работы персонала, и за этот срок мы смогли выйти на уровень работы с компаниями мирового масштаба. Достичь таких результатов удалось за счет ясной миссии, опытной команды отличных специалистов, четко структурированной системы электронного документооборота (СЭД), профессионального подхода к работе и больших амбиций.

Чтобы ознакомиться с инструкцией выберите файл в списке, который вы хотите скачать, нажмите на кнопку "Загрузить" и вы перейдете на страницу загрузки, где необходимо будет ввести код с картинки. При правильном ответе на месте картинки появится кнопка для скачивания.

Если в поле с файлом есть кнопка "Просмотр", это значит, что можно просмотреть инструкцию онлайн, без необходимости скачивать ее на компьютер.

Чтобы ознакомится с другими нашими инструкциями воспользуйтесь поиском вверху страницы, либо через навигацию на главной странице.

В случае если инструкция по вашему не полная или нужна дополнительная информация по этому устройству, например драйвер, дополнительное руководство пользователя (у одного устройства может быть несколько руководств, например, руководство по обновлению), прошивка или микропрограмма, то вы можете задать вопрос модераторм и участникам нашего сообщества, которые постараются оперативно отреагировать на ваш вопрос.

Водонагреватель накопительный Ariston ABS VLS PW 50 объёмом 50 литров, с двумя нагревательными элементами и системой безопасного отключения воды - надежное устройство для вашего комфорта. Цифровой дисплей с функцией программирования позволяет быстро выполнить первый нагрев воды за счет второго нагревательного элемента до 80°С. Специальная форма рассекателя NANOMIX обеспечивает получение большего объема воды за меньшее время. Кроме того, водонагреватель накопительный Ariston ABS VLS PW 50 оснащен профессиональной системой защиты от бактерий ECO и специальным покрытием AG+ для защиты от коррозии. С технологиями Ariston вода в вашем доме всегда будет чистой и горячей!

The MK 41 Vertical Launching System (VLS) is the worldwide standard in shipborne missile launching systems. Under the guidance of the US Navy, Martin Marietta performs the design, development, production, and field support that make the battle-proven VLS the most advanced shipborne missile launching system in the world. The Mk 41 VLS simultaneously supports multiple warfighting capabilities, including antiair warfare, antisubmarine warfare, ship self-defense, strike warfare, and antisurface warfare.

MK 41 is a fixed, vertical, multi-missile storage and firing system that lets Navy vessels launch significant firepower. The capability of VLS to simultaneously prepare one missile in each half of a launcher module allows for fast reaction to multiple threats with concentrated, continuous firepower. The Mark 21 VLS launch canister for the SM-2 Block IV round and its variants, and the Mark 14 canister for the Tomahawk land attack missile (TLAM) cannot be transferred at sea. They are several thousand pounds too heavy for the existing handling crane. A US Navy warship that runs out of SM-2 Block IVA, SM-2/LEAP or TLAM missiles has to break off its patrol and proceed to port to reload. In Fiscal Year 1996 the US Navy started work on the Concentric Canister Launcher (CCL), a universal launch system able to handle the Tomahawk, SM-2 Block IV and Evolved Seasparrow Missile (ESSM). Designed to be capable of simultaneous and co-ordinated launch of multiple missile types, the CCL will be a modular automated design compatible with reduced manning levels.

The US Navy currently deploys MK 41 VLS - on AEGIS-equipped Ticonderoga-class cruisers and Spruance- and Arleigh Burke-class destroyers - and plans to use it on next generation of surface ships, the LDP17, DD-21 and CG-21. In production since 1982, VLS is continually upgraded to incorporate new technology and integrate new missiles. Additionally, MK 41 VLS is the choice of eight other international navies - including Canada, Japan, Germany, Turkey, Spain, Netherlands, Australia and New Zealand - a number that is expected to grow as a result of significant ongoing international marketing campaigns.

The Vertical Launching System (VLS) Mk 41 is a canister launching system which provides a rapid-fire launch capability against hostile threats. The missile launcher consists of a single eight-cell missile module, capable of launching SEASPARROW missiles used against hostile aircraft, missiles and surface units. Primary units of the VLS are two Launch Control Units, one 8-Cell Module, one 8-Cell System Module, a Remote Launch Enable Panel and a Status Panel.

The Launch Control Units receive launch orders from the Multi-Function Computer Plant (MFCP). In response to the orders, the Launch Control Units select and issue prelaunch and launch commands to the selected missile in the VLS launcher. During normal VLS operations, each Launch Control Unit controls half of the Launch Sequencers in the launcher. Either Launch Control Unit can be ordered by the MFCP where one Launch Control Unit is offline and the other Launch Control Unit assumes control of all Launch Sequencers in the launcher.

The 8-Cell Module consists of an upright structure that provides vertical storage space for eight missile canisters. A deck and hatch assembly at the top of the module protects the missile canisters during storage and the hatches open to permit missile launches. The plenum and uptake structure capture and vent missile exhaust gases vertically up through the module to the atmosphere through the uptake hatch. Electronic equipment mounted on the 8-Cell Module monitors the stored missile canisters and the module components and assists in launching the missiles.

The 8-Cell System Module is like an 8-Cell Module with addition of the 60 Hz and 400 Hz Power Distribution Panels; the Damage Control Junction Box; the System Lighting, Power Receptacle, and Telephone Junction Box; and the System Transformer Platform that serve the entire launcher. The 8-Cell System Module receives and distributes power and control signals from outside the launcher to all the modules and collects control and damage control signals from the modules and sends them outside the launcher.

The Status Panel receives module status and launcher hazard signals from the monitoring assemblies within the launcher. Status and hazard conditions are displayed on the Status Panel. The Status Panel also sends launcher hazard and module status signals to the ship Central Control Station. The Status Panel receives enable signals from the Remote Launch Enable Panel that enables launcher power and the launch enable function within the launcher if the Status Panel is in remote operation.

The modular MK 41 is adaptable to short-length configurations to enhance ship and weapon applicability potential worldwide. Responding to continued development interest from US Navy allies, the USN is pursuing a VLS MK 41 tactical-length launcher initiative to provide for shipboard loadout and rapid firing of existing Antiaircraft Warfare (AAW) and Antisubmarine Warfare (ASW) tactical weapon types, and allow significant expansion in alternate ship mounting arrangements (such as in superstructure areas) and for reduced draft hulls. The engineering development for the tactical-length launcher has been completed. The tactical-length launcher uses the vast majority of the strike-length VLS MK 41 components and remains an eight-cell module with full VLS MK 41 system capability.

A new modernization plan for surface combatants would decommission some ships early, but would boost the firepower of the remaining force by adding the Vertical Launch System (VLS). The five TICONDEROGA-class cruisers in the fleet without VLS would receive the system: USS TICONDEROGA (CG 47), USS YORKTOWN (CG 48), USS VINCENNES (CG 49), USS VALLEY FORCE (CG 50) and USS THOMAS GATES (CG 51).

Mk 41 Vertical Launching (VLS) Missile ComplimentMissile Canisters in Service and Deployed:

A vertical launching system (VLS ) is a modern type of missile -firing system used aboard the submarines and surface vessels of several navies around the world.

Derived from the launch systems developed for ballistic missiles aboard SSBNs. a VLS forms a scaled-down equivalent for launching cruise missiles such as the Tomahawk and surface-to-air missiles (SAMs) such as the Standard missile.

When installed on a SSN (nuclear-powered attack submarine), a VLS allows a greater number and variety of weapons to be deployed in comparison to using only torpedo tubes. A VLS allows surface combatants to have a greater number of weapons ready for firing at any given time compared to older launching systems such as the Mk-13 single-arm and Mk-26 twin-arm launchers, which were fed from behind by a magazine below the main deck. In addition to greater firepower, VLS is much more damage tolerant and reliable than the previous systems, and has a lower radar cross-section (RCS). The U.S. Navy now relies exclusively on VLS for its guided missile destroyers and cruisers. an advanced Mk 57 VLS system is projected to be used on the new Zumwalt class destroyer. and the older Mk-13 and Mk-26 systems remain in service on ships that were sold to other countries such as Taiwan, Greece, and Poland.

Fri May 12 2000 at 6:01:05

Vertical Launch System (VLS) - an arrangement for launching guided missile weapons vertically from a prepackaged canister. This maximizes both weapon storage space and availability as well as minimizing complexity - the launch system is open to the sky, meaning that the weapons need not be moved or aligned prior to launch, relying instead on their onboard guidance to align them once they have left the launch system. Typically, these systems are used aboard naval vessels, where space is tightly constrained and complex systems (such as moving launchers or reloading rails) are difficult to maintain.

The U.S. Navy's current VLS system is the Mark 41 VLS. It consists of several components, including the launch tubes (called 'cells') which come in blocks of eight (2x4); a remote control console, and a status indicator panel, both of which are mounted elsewhere inside the ship. In addition, there are control computers for the system. Additional eight-cell modules can be added to the base system to produce installations with greater magazine size; at least one must be a 'system module' which contains the control systems for the cells. In addition, a special module can be installed of which four cells have been removed in favor of a built-in crane, allowing the ship to lift and load its own replacement canisters into the cells from alongside without requiring a ship or dock with a crane of its own. The crane cannot, however, handle all types of canister - the Standard SM-2 Block IV and the Tomahawk TLAM canisters are too heavy to be reloaded at sea using the built-in crane and must be reloaded in port.

There are two types of Mk. 41, differentiated by the length (or depth, depending on how you look at it) of the launching tubes. The VLS Strike can take the longest available canisters, allowing for longer (and hence longer range and greater payload) weapons. The VLS Tactical is shorter.

Various different types of missiles can and are mixed into the loadout of a ship's VLS, including strike and SSD (ship self defense) loads. At present, the U.S. Mk. 41 can be loaded with any of the following types of canister:There are additional canisters in development or early deployment, including those carrying navalised versions of the Army ATACMS missile as well as single and dual-missile canisters for the Navy's Land-attack Standard Missile. There is an Evolved Sea Sparrow (ESSM) canister quad missile canister which, in addition to being loadable in Mk. 41 VLS systems, may be usable in angled rail launchers as 'single-shot' self-defense weapons for smaller ships which do not have VLS.

VLS systems differ from the classic 'missile tube' aboard an SSBN or SSGN in that rather than each missile tube containing a full set of control systems and being essentially an independent system, along with having separate ejection charges for underwater launch, the VLS is deliberately designed as a modular system with reloadable cells for use in a variety of installed spaces.

Other nations have their own versions of VLS, of course! Russian yards have been installing VLS systems to launch SAM s and cruise missiles for at least as long, if not longer, than the U.S. Both nations will happily sell VLS systems to allies and nonaligned customers, and they can be found on ships of all nations. They're not only limited to surface vessels; the U.S. SSN 688 Los Angeles flight II and later boats have VLS tubes in the bow to allow them to launch Tomahawk cruise missile salvos without having to use the torpedo tubes.

Transitional Man brings up some excellent points about the comparative advantages and disadvantages of the VLS system. On the plus side, using prepackaged rounds in deck-accessible slots which serve for both storage and launch means that there is no need to maneuver large, heavy, fragile and dangerous objects through the interior of the ship into magazines. This eliminates the requirements for passageways for both onloading the rounds during resupply, and for sending rounds to launcher s during combat - as well as eliminating the need for large and complex mechanisms to move the rounds at speed. Saving space, weight, power requirements and complexity on board a warship are always good things; each savings allows other systems to be put aboard to either increase the fighting capability of the ship or to increase its resiliency under fire and underway. Better damage control. better compartmentalization, more redundant systems, more living space - all will pay dividends of one form or another.

There are, of course, disadvantages as well. TM 's initial message to me emphasizes one of them - despite the addition of onboard cranes for canister handling, reloading a VLS system at sea is much more difficult than reloading a traditional magazine. This is because while ammunition for a traditional ship need only be transferred horizontally before being immediately locked to a rail system for transfer into the magazine, a VLS canister must be raised vertically above the deck so that it can be lowered into its slot. This is suboptimal on a ship at sea, which will be rolling around an axis somewhere near its waterline. As a result, the canister and its handling equipment will be moving like an inverse pendulum - not something to make life easy when mucking about with multiple tons of high explosive and rocket fuel. Reloading hence can only be done on smoother seas, and will take more time.

The U.S. Navy presently has no serious opponents for blue-water supremacy - and most of its actual threats are aerial, submarine or small-boat rather than major surface combatants. As such, it has a need for fast-response and quick salvos of missile weapons for air defense, or heavy missile weapons for long-range shots. There is less of a requirement for sustained missile fire engagements under attack, with ammunition below deck in protected magazines. Rotating launchers with missile handing rails introduce both complexity and delay - which VLS avoids.

Given that the U.S. Navy presently should be able to maintain sea control to the point of being able to find a quiet spot to reload, the disadvantages of the VLS system apparently were not enough to overcome its advantages.